Unlocking the Secrets of Innovating Silicon: A Glimpse into the Future of Electronic Chip Technology Will Leave You Awestruck!

Technology has revolutionized every aspect of our lives, and at the heart of this digital transformation lies the tiny yet powerful electronic chip. From smartphones and laptops to cars and medical devices, electronic chips play a vital role in the functioning of countless modern devices. But have you ever wondered how these chips are made? In this curated guide, we will unravel the hidden wonders of microelectronics and take you on a journey through the intricate process of making electronic chips.

The Evolution of Electronic Chips

To truly understand the complexity of making electronic chips, we must first explore their evolution. Microelectronics, or the study and manufacture of electronic components and circuits in tiny sizes, has come a long way since its inception. From the discovery of the transistor in the 1940s by Bell Labs to the miniaturization techniques developed in the 1960s, the field of chip manufacturing has witnessed rapid advancements.

The Design Phase

Before delving into the manufacturing process, it’s crucial to understand the importance of chip design. The design phase sets the foundation for the final product’s capabilities. Complex software tools and methodologies are employed to design integrated circuits, ensuring optimal performance and functionality.

A revolutionary concept in chip design is System-on-a-Chip (SoC), which integrates multiple functions onto a single chip. SoCs have transformed the landscape of modern technology, enabling devices to perform multiple tasks simultaneously while occupying minimal space.

“The future may seem elusive, but with innovative chip technology, we are unraveling limitless possibilities for a better tomorrow. Join the journey to #Unveil. #Innovation #SiliconValley”

Semiconductor Materials

When it comes to the actual manufacturing of electronic chips, semiconductor materials play a vital role. Silicon, with its excellent electrical properties, is the most widely used material in chip manufacturing. However, other materials such as gallium arsenide and germanium also have their own specific applications in microelectronics.

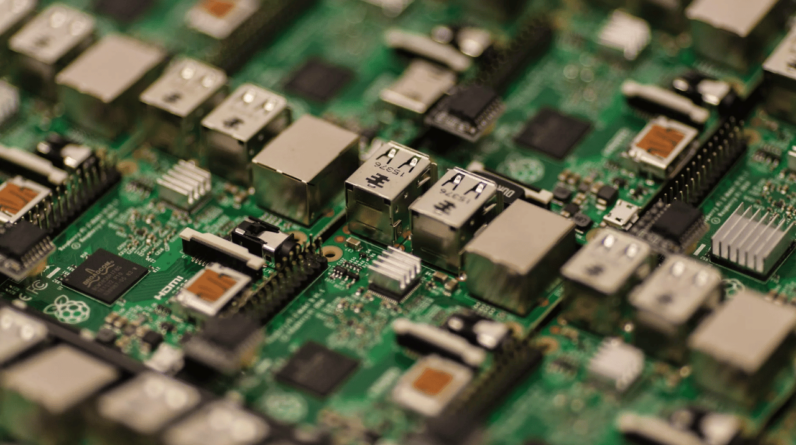

Image courtesy of www.blog.baldengineering.com via Google Images

Choosing the right semiconductor material is crucial as it determines the behavior and performance of the chip. For example, gallium arsenide is often used in high-frequency applications due to its superior electron mobility. The right material selection ensures optimized chip performance for specific applications.

Fabrication Techniques

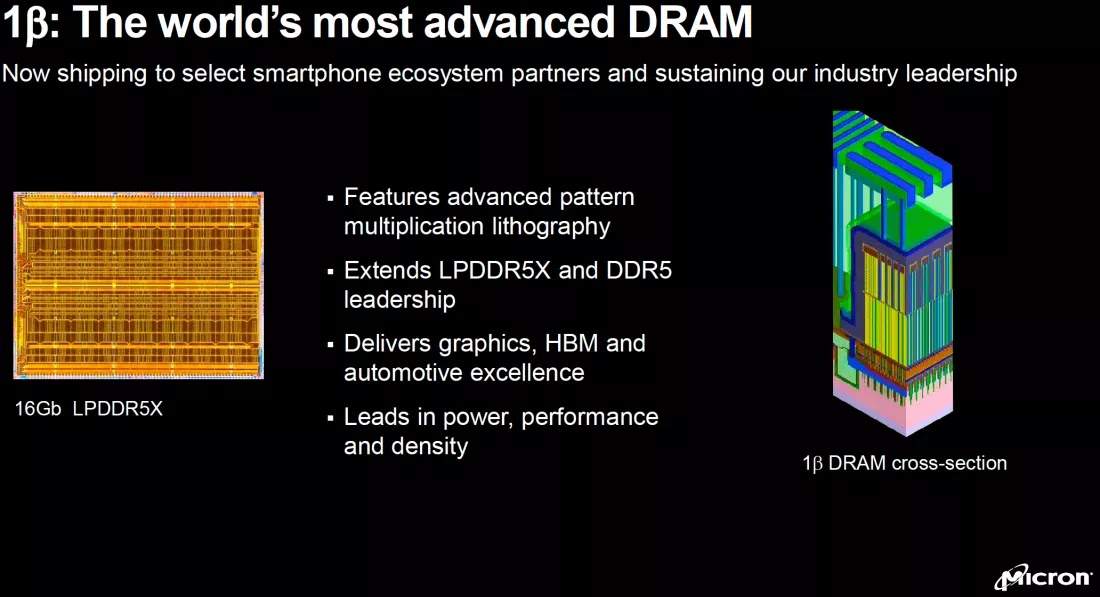

Once the design and materials have been determined, the actual fabrication process begins. At the heart of this process lies lithography. Lithography involves creating patterns on a wafer by selectively applying or removing materials. Photolithography, using light to transfer a pattern on a mask to the wafer, is the most common technique used. Advanced methods like electron beam lithography allow for even smaller feature sizes and greater precision.

Other crucial fabrication techniques include etching, deposition, and polishing. These steps help shape the materials deposited on the wafer, forming intricate layers and structures necessary for the chip’s functionality.

Layer by Layer: The Chip Manufacturing Process

Now, let’s take a closer look at the step-by-step process of making a chip. It all starts with wafer preparation. A thin circular wafer, typically made of silicon, is meticulously prepared by cleaning and polishing to ensure a defect-free surface.

Image courtesy of www.hpcwire.com via Google Images

Next, the fun begins. Layer by layer, various structures and components are built on the wafer’s surface. The heart of any chip is the transistor, a tiny switch that controls the flow of electricity. These transistors are interconnected using complex wiring schemes that enable seamless communication between different components.

One of the critical steps in chip manufacturing is doping, where impurities are intentionally introduced to modify the electrical properties of certain regions. This process enables controlled electrical behavior and is crucial for the proper functioning of the chip.

Testing and Quality Control

Once the chip has been fabricated, it undergoes a series of rigorous testing procedures to ensure its quality and performance. Testing is carried out at various stages, starting from the early manufacturing stages and continuing until the final product.

Different testing methods are employed, including functional testing, electrical characterization, and reliability testing. These tests identify defects and ensure that the chip meets the required specifications and performance standards. Through these quality control measures, manufacturers strive to minimize defects and deliver reliable, high-performance chips to the market.

Conclusion

The process of making electronic chips is a complex and fascinating journey that showcases the marvels of microelectronics. From the design phase to the final testing, each step plays a critical role in transforming raw materials into cutting-edge technology.

The advancements in chip manufacturing have propelled us into the digital age, enabling the innovation and convenience we experience today. As we continue to uncover new materials and fabrication techniques, who knows what the future holds for electronic chip technology. So next time you hold a smartphone in your hand or drive a smart car, take a moment to appreciate the incredible journey that electronic chips have undergone to make it all possible.

Read also:

Datafication: The Power of Information for Business Success

The Potential of Autonomous Systems: A Journey into the Future